模块化和可扩展输送线的分布式控制技术

图尔克(Turck)TBEN 系列中的紧凑型 TBEN I/O 模块不仅能够控制辊道上的滚筒电机,还能实现整个输送线的数字化,同时确保内部物流的透明度。德国行业期刊《KEM》主编迈克尔·科尔班(Michael Corban)采访了图尔克的四位专家弗兰克·莫拉西(Frank Morassi)、霍尔格·施皮斯(Holger Spies)、弗雷德里克·尼切(Frederik Nitsche)和亨德里克·施纳贝尔(Hendrik Schnabel),以了解分布式自动化、模块化和数字化如何实现灵活可扩展且高可用性的输送线——当与用于输送货物识别的 RFID 技术相结合时,这是一种特别高效的方法。

图尔克的这款内部物流产品能够应对哪些挑战?

Frank Morassi(内部物流垂直行业销售经理):在内部物流领域,没有两个系统是完全相同的——灵活性至关重要。这不仅体现在所用组件方面,还体现在能够快速重新设计输送系统,以满足当今频繁且快速变化的需求。在机械工程方面,答案是模块化;在自动化方面,则是分散式自动化与数字化相结合——而这正是我们的专长所在。通过这种方式,我们可以实现模块化且灵活可扩展的输送线——在需要时提供高可用性和零压力积存运行。采用这种方法,我们能够解决未来几年将日益增多的诸多任务。

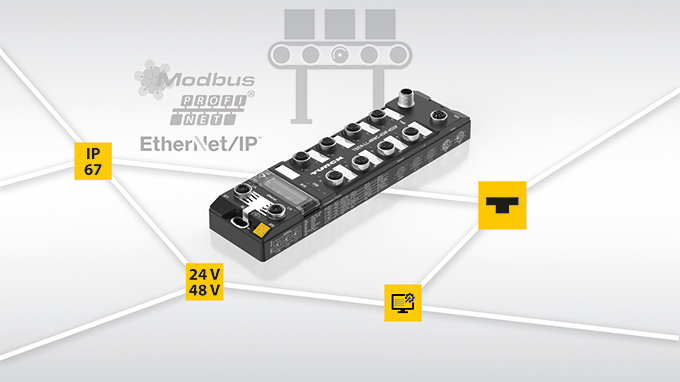

如果需求发生变化,除了需要快速重新设计系统外,还需要具备可扩展性。模块化设计和分散式自动化使得输送模块能够快速轻松地适应和扩展,以适应新的输送线布局。有了智能且坚固的 I/O 模块,布线工作量微乎其微——这些模块还具备控制功能,以及用于连接执行器和传感器的接口,包括 24 伏或 48 伏电源。由于我们的产品系列始终基于模块化和整体概念,图尔克能够为内部物流提供一站式解决方案——并通过图尔克自动化套件(Turck Automation Suite)将分布式自动化、可追溯性、状态监测、可扩展性、快速上市时间和数字服务集于一体。在此还需提及我们在 RFID 方面的专业知识。

您可以展开说一说吗?

Morassi: 当涉及多重作业环节,如组装、焊接、钎焊、包装、储存、暂存、转移或重新包装时,准确记录每个包装箱和组件的当前位置非常重要。我们可以用RFID技术来很好地实现这一点,而不仅仅是在出入库区域通过安全门进行记录。我们可以在各个工作站进行记录并提供给更高层级的系统。与条形码不同,RFID的一大优势是不仅能读取载码体,还能进行写入操作。例如,可以在装配过程中轻松提供所安装部件和组件的序列号信息,从而保证可追溯性。

您还提到了快速上市时间...

Morassi: ...这是分布式自动化的优势之一。我们可以更快地实施系统,因为分布式系统是自主运行和测试的。这使得实施新系统甚至扩展系统都能够更快完成。同时,我们还有机会轻松地收集和处理数据。这可以创造附加值,例如在维护任务中,可以通过云端进行数据分析。

这正是我们的自动化软件TAS(图尔克自动化套件)发挥作用的地方。该工具使我们能够轻松整合和集成所有组件。理想情况下,输送线的每个元件都配备了我们的I/O模块,因此可以记录相关数据并将其发送至更高层级的控制系统。

智能I/O模块也有控制器——本地与更高层级的控制器如何互动?

Holger Spies(销售项目经理):通过在输送线上分布式安装TBEN模块,我们不仅能完全控制特定输送机模块的滚筒电机,还能通过集成的控制器解决可以通过本地控制的各种指令。需要强调的是,我们甚至能处理具有实时性要求的任务。这样,更高层级的控制器无需针对单个模块执行任何具体任务,而只需统筹整个系统的运作。除了模块的控制任务外,还可收集转发数据用于预见性维护。

我举个简单的例子:假设工作站X要分拣一个包裹,我们就可以通过模块本地记录信息并进行转发。换言之,我们可以识别出包裹并通过本地的分布式自动化功能控制分拣的单元。对于实时应用也同样如此。此时,无需通过中央控制器传输信息。例如,这使得电动滚筒能够根据相应任务进行本地控制。基于CAN的通信协议还支持同时发送额外数据并运行特定的配置文件,或者反过来读取温度、电流和电压等,从而实现数字层面的一致性,并消除使用模拟接口的限制。数字化使我们能够维持整个系统状态的透明性。

这样就能实现状态监测了?

Spies: 是的!这是因为我们现在能确定每个电动滚筒所需的电流分量,因此不仅开辟了进一步控制选项的可能,还为实施预见性维护奠定了基础。只有当具备这种数据透明性时,系统制造商才能提前为其客户提供更换特定电动滚筒的能力,例如当滚筒在运行特定时间后电流消耗开始变高时。

总之,分布式自动化使我们同样能够在现场本地处理实时应用,从而实现全面灵活性,包括从控制和扩展输送线直至实施预见性维护解决方案。

使用的智能I/O模块还有哪些其他特点?

Frederik Nitsche(工厂自动化系统产品经理):出于可持续性考虑,我们一直在制造适用于严苛环境条件的IP67模块。抗振动性能在内部物流领域尤其重要。此外,我们还支持为电机提供48V电源,这看似简单,却能使工作电流减半,这对于大规模内部物流系统尤其重要。每个图尔克模块都可以为四个滚筒电机供电并实施控制,从而管理整个输送机模块。

正如前面提到的,我们的控制功能不仅限于滚筒电机,还可以执行其他任务。总体而言,这可以为内部物流专家打造简单而灵活的分布式逻辑系统,不仅能够高效应用于输送机模块,还能实现零压力积放输送。因此,这是实现滚筒输送系统分段自动化的卓越解决方案。

我们是否必须依赖特定制造商的滚筒电机?

Nitsche: 我们目前支持来自MTA、MPC和Interroll的基于CAN总线的电机。本着模块化的核心理念,我们将实际控制逻辑和滚筒数字连接集成在一起。这样一来,就无需有人操心数据映射问题,而且您可以随时通过Profinet或EtherNet/IP控制电机速度,或者反过来读取数据以进行预测性维护。例如,基于我们的TBEN-LL4RM-4DI-4DXP I/O模块,我们为胜斐迩(SSI SCHAEFER)进一步开发了一个模块,以创建“输送机控制单元”。除了为滚筒电机提供48伏电源、为传统执行器提供24伏电源、与电机进行CAN通信以及与控制器进行Profinet通信外,该模块还需要具备用于外部触发信号或执行器的数字输入和输出。除了四个常规I/O端口外,该模块还提供了四个DXP端口,这些端口既可用作输入端口,也可用作输出端口。

Spies: 正如前面提到的,这些模块还可用于解决实时控制任务,特别是与图尔克的RFID系统(如我们新的RFID通道)结合使用时。在内部物流中,我经常需要完成这样的任务,比如检查一个箱子里是否真的有五个标签——如果只有四个,我就必须能够直接将箱子弹出并退回。关键因素始终是让用户能够自行决定是在相关模块上本地解决此类任务,还是集中解决——我们两种方式都能实现。这对于系统扩展和改造而言,具有巨大的优势。

集成这种 RFID 隧道容易吗?

Hendrik Schnabel(RFID UHF 系统产品经理): 非常简单,尤其是可以扩展。我们的 RFID 隧道提供了一个 RFID 读取点,可以非常容易地连接到输送系统上。我之所以强调这一点,是因为在主要采用金属传送带技术的环境中安装这种读取点并非易事。为了获得可重复的读取结果,读取点必须有良好的屏蔽并与传送带对齐。我们的 RFID 隧道已经包含了所有这一切,因此用户在扩展系统时可以轻松增加更多的隧道--一切都已预先组装好。射频识别(RFID)技术在此也发挥了重要作用,因为随着内部物流对识别的要求越来越高,传统的条形码已经难以满足我们的用户。

您之前提到了金属环境——对于在金属或液体上读取RFID标签的问题,是否已经找到了解决方案?

Schnabel: 从根本上来说,这仍然是个问题——但已经有解决方案了,比如使用特殊的金属标签。对于这类需求,我们还提供咨询服务——因为这些情况通常很复杂,需要仔细研究。不过,如今的内部物流主要使用塑料容器和托架,因此读取标签并不是问题。

作者 | Michael Corban 是行业期刊《KEM 设计与自动化》(KEM Konstruktion | Automation)的主编

输送技术未来——模块化与去中心化!

选择国家

图尔克全球